MAIN BUSINESS CONTENTS

On-site Maintenance Service

Our experienced engineers provide service support for maintenance, inspection, overhaul, and troubleshooting of customer equipment.

Alternative Parts Development

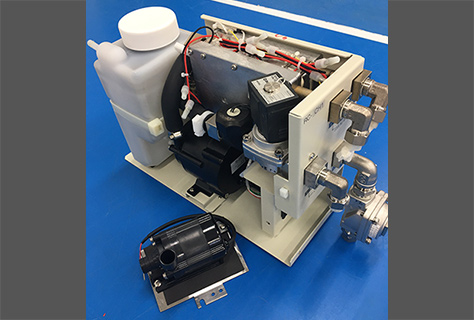

Repair Work

- Circulator

- Main repair items

- Pump, resistance temperature detector replacement

- Replacement of Pelche element and flow switch

Shipping inspection is conducted based on our specified items after repair.

CONTACT

CONTACT